At M-TEST we are dedicated to shaping the future of passenger safety transportation, to make journeys safer. With state-of-the-art facilities and capabilities in aerospace, automotive and emergency services, we stand at the forefront of passenger safety research and development.

Our vision is to make journeys safer by uniting technology, expertise and best practices for passenger safety.

Company Overview

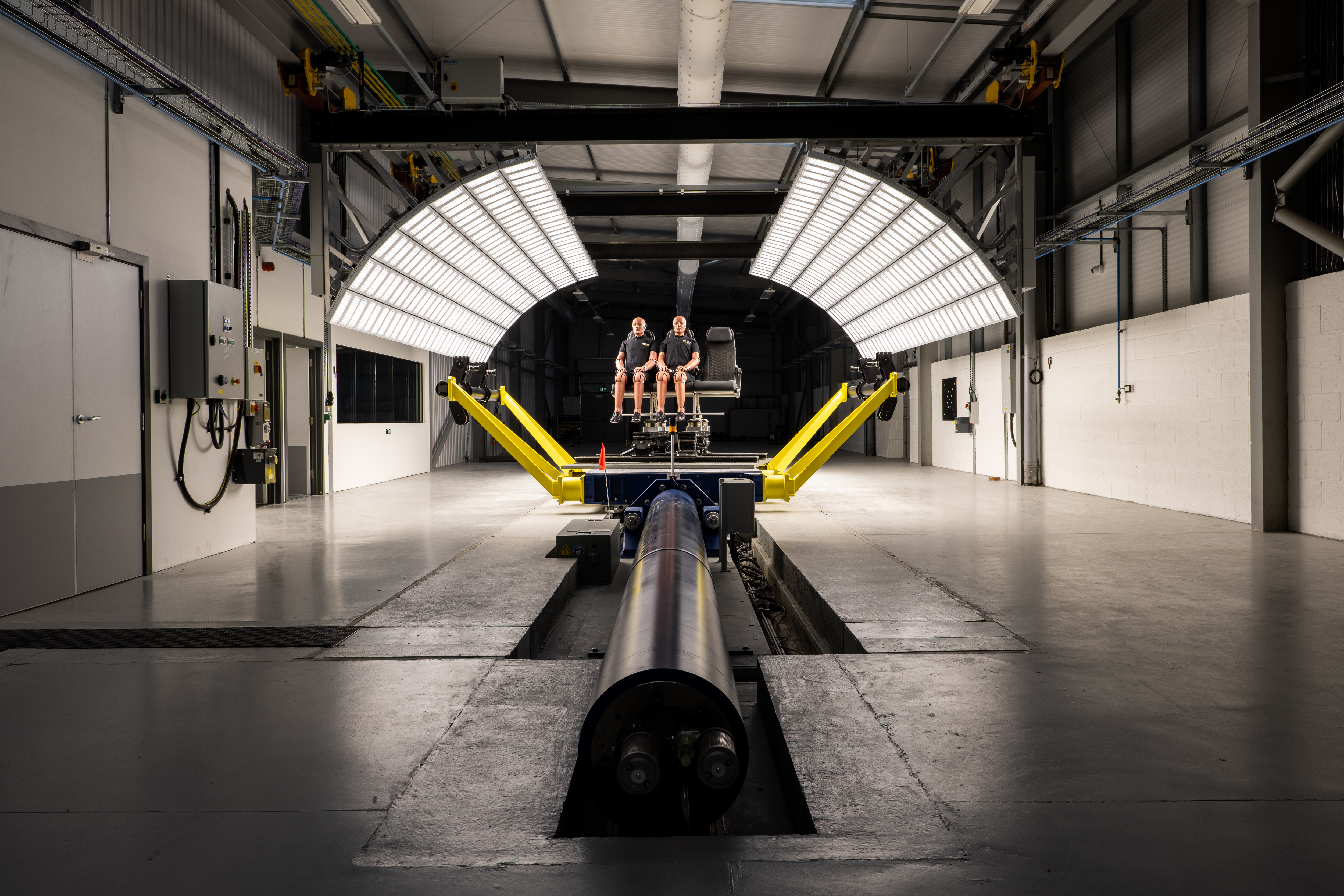

Our 407m² facility is the largest commercially available dynamic testing facility in the UK and is located next to our sister company Mirus Aircraft Seating HQ in Hingham, Norfolk.

Featuring the latest in aircraft testing technology, our laboratory uses a state-of-the-art, dynamic testing that is used to simulate real world crash scenarios.

The 30m-long Servosled is designed to simulate impact tests defined in specifications for multiple capabilities, which include but not limited to the following:

- Automotive (FMVSS, ECE UN, Euro ENCAP)

- Aerospace (CS23/25/27/29, AS8049, AC25.562)

- Rail (GMRT2100)

- Medical (BS EN1789:2020, ISO 7179-19)

- Military (Defstan, etc.)

Agile and responsive

Being the largest commercially available test facility in the UK, our full-service operation reduces development times and carbon footprint by shipping seats within the UK, for UK based suppliers, manufacturers and OEM's making M-TEST more agile and responsive to our customers needs.

Our testing solutions span aerospace, automotive, emergency services, defence and motorsport industries.

Our Seattle Safety 2.0MN Servo Sled with servo-hydraulic control provides highly accurate and repeatable acceleration and velocity profiles with extremely high frequency response. New pulses can be quickly tuned to complete all tests as quickly as possible. With closed-loop acceleration and pressure feedback, new pulses can be matched in three tuning shots or less. It's advanced control system allows the system to perform a wide range of tests with accuracy, repeatability and confidence.

The IDT CCM-3510 camera we use is a rugged, high-G and vibration rated camera designed for use in on-board vehicle impact testing. It supports 2560 x 1440 resolution with up to 1,000 fps and are equipped with MicroSD cards to increase storage capacity

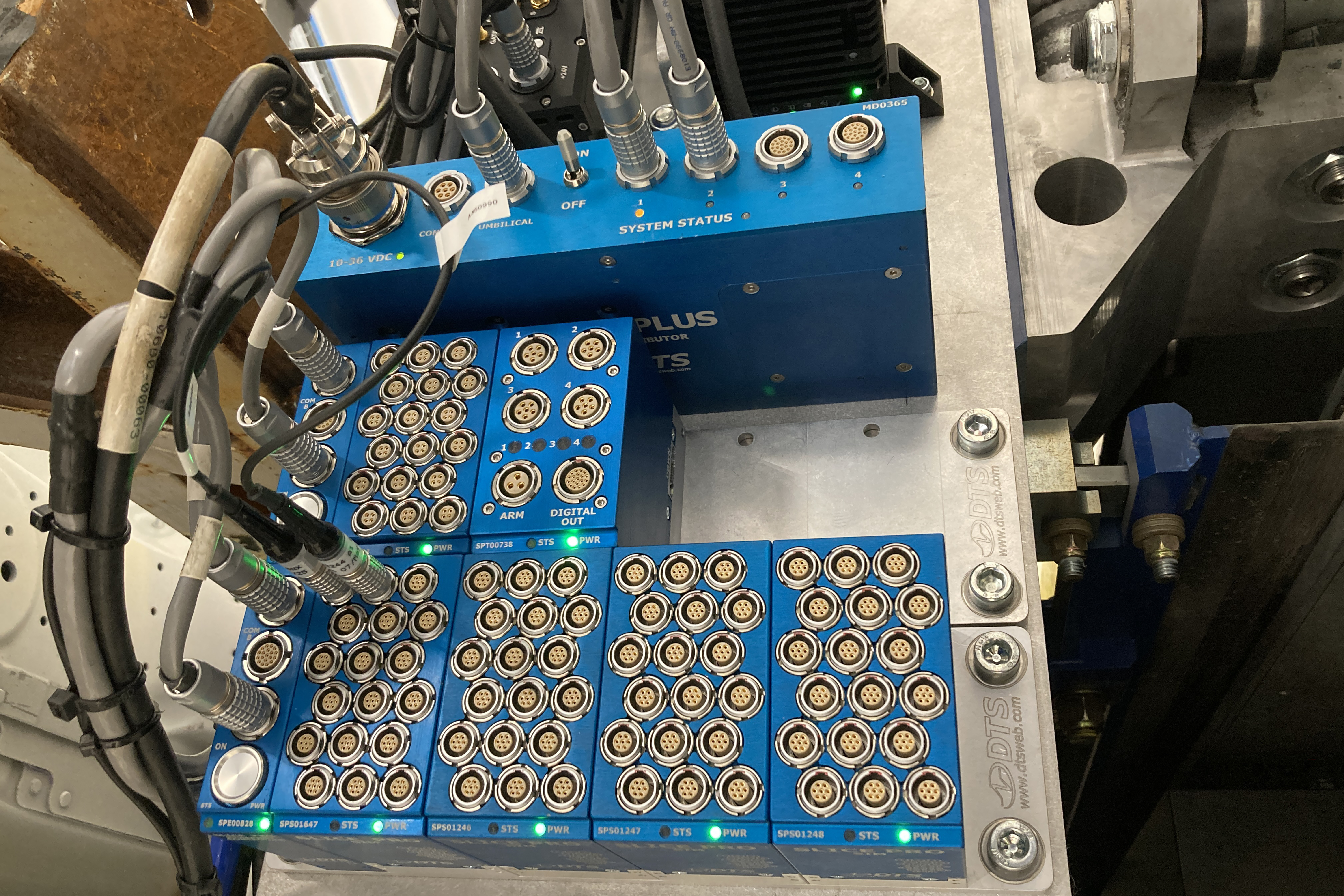

The DTS SLICE PRO is a shock-hardened, data acquisition system flexibility and reliability that writes data directly to non-volatile flash memory, making it ideal for a variety of critical applications including aerospace and automotive safety testing. Modular solution, easily configures to create the exact features and channel count needed. Daisy-chain up to hundreds of channels per test. User-selectable sampling rates, data writes directly to 16 GB non-volatile flash memory. Complies with ISO 6487 and SAE J211 recommended practices, as well as NHTSA and FAA requirements.

Our promise to safely secure your data.

Our unmatched confidentiality guarantees privacy both on and off site for all clients.

Facility access.

The M-TEST facility is adjacent to our sister company Mirus Aircraft Seating. A Paxton door lock system restricts movement between the two facilities.

Solely our M-TEST team have access into the facility.

The main entrance is either through the Mirus reception or using the door to the front of the test facility.

All other access to the test facility has be authorised prior to visiting.

Servers and data control.

All customer information is confidential and will not be stored on removable media unless it is appropriately encrypted.

All confidential information and test data is stored solely within the M-TEST network and exclusively shared with the respective customer.

The M-TEST servers have a cloud-based back-up system with full disaster recovery.

Access to information on these systems can only be carried by the M-TEST team.

Our journey.

We are committed to providing the latest technology to ensure the best in passenger safety. It is a journey, and we’re well on our way.

2022

Facility started construction

Facility commissioned

First aviation seat test conducted December 2022

2023

M-TEST officially launched

UKAS accreditation received for aircraft seat testing

First external customer test

2024

First automotive test conducted

First ambulance test conducted

Military customer work carried out

First EU customer

2025

UKAS accreditation for ambulance testing

Proud to host our first dynamic testing course (ICAO)

We appreciate your interest in M-TEST, our customer support team are here to help you with any queries you may have.

Dedicated to making your journey safer

Please enter your details to download resources

© 2026 MTEST Dynamic Testing